Woodturning is a delicate art that requires both skill and the right tools to achieve the desired results. One of the most essential tools for woodturners is the cutting tool, and in recent years, carbide cutters have become a game-changer in the craft. These carbide tools, with their unmatched durability and precision, have quickly gained popularity over traditional high-speed steel tools. But even the best carbide cutters wear down over time, making replacement carbide cutters an essential part of any serious woodturner's toolkit. These cutters not only extend the life of your tools but also improve your turning experience by maintaining sharpness and offering enhanced cutting performance.

Carbide cutters, as opposed to traditional steel tools, are made from a composite material that combines carbon and tungsten, two incredibly hard substances. This composition gives carbide cutters a level of sharpness and edge retention that's superior to many other materials, which is why they are preferred for heavy-duty woodturning projects. Whether you are working with hardwoods, softwoods, or more exotic materials, carbide cutters allow for smoother, more efficient cutting with less effort. However, like all tools, they eventually wear down, especially when working with tougher or denser woods. That's where replacement carbide cutters come in.

Replacing a worn carbide cutter is a straightforward yet crucial part of maintaining your tools and ensuring consistent, high-quality work. As the carbide edges dull, they no longer cut as cleanly, and this can lead to tear-out, burning, or poor surface finishes. By regularly replacing the cutters, you avoid these problems and maintain the quality of your turns. The durability of carbide also means that when you replace a cutter, the new one can often outlast several replacements of traditional steel cutters, saving both time and money in the long run.

One of the key advantages of using replacement carbide cutters is their ability to maintain sharpness over extended periods. Unlike traditional tools that require frequent honing or sharpening, carbide cutters are designed to resist wear. When a cutter begins to show signs of dullness, it's often just a matter of swapping it out for a new one, rather than spending time and effort on sharpening. This convenience not only saves you time but also ensures that your cuts remain smooth and precise throughout the project. The sharpness and precision of a new carbide cutter can make a huge difference in the final product, resulting in smoother finishes and cleaner cuts.

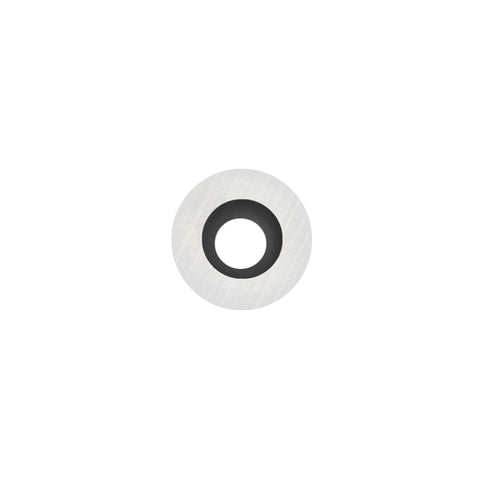

Carbide cutters also come in a variety of shapes and sizes, designed for specific applications and preferences. Round, square, and diamond shapes are common, each offering different advantages depending on the type of turning being done. For instance, a square cutter is ideal for making straight cuts and shaping edges, while a round cutter is better for creating smooth, curved surfaces. The diamond-shaped cutter is excellent for fine detail work and finishing. Having access to replacement carbide cutters in these different profiles means that woodturners can maintain a wide range of cutting capabilities without having to buy entirely new tools. This versatility is one of the reasons why carbide cutters have become a staple in modern woodturning.

Another reason woodturners gravitate towards replacement carbide cutters is the ease of use. For beginners or those new to the craft, carbide cutters eliminate some of the complexities of traditional sharpening techniques. With a carbide tool, there is less reliance on manual sharpening stones or jigs, making it easier for woodturners to focus on their technique rather than the upkeep of their tools. This simplicity allows more time for creativity and experimentation, particularly when working on intricate projects like bowls, spindles, and intricate decorative pieces.

The use of replacement carbide cutters can also enhance safety. A dull cutting edge can be dangerous because it requires more force to cut through the wood, increasing the risk of the tool slipping or binding. A fresh carbide cutter, however, requires less effort to make clean cuts, reducing the strain on both the tool and the woodturner. This reduces the likelihood of accidents, making the turning process not only more efficient but also safer.

While carbide cutters offer numerous benefits, they do come with some considerations. For example, carbide tools can be more expensive upfront compared to traditional steel tools. However, the longevity of carbide cutters, coupled with the ease of replacement, makes them a cost-effective investment over time. Additionally, carbide cutters tend to be more brittle than steel, meaning that improper use or dropping the tool can cause the cutter to chip or break. Nonetheless, when used properly, they outperform most traditional tools in terms of cutting efficiency and durability.

In conclusion, replacement carbide cutters are an essential component of any woodturner's toolkit, offering numerous advantages in terms of longevity, precision, and ease of use. Whether you're a seasoned woodturner or a beginner, keeping your carbide cutters sharp and well-maintained ensures that your projects continue to reflect the quality and craftsmanship you desire. With their ability to maintain a sharp edge over extended periods and their variety of shapes to suit different turning needs, replacement carbide cutters have revolutionized the way woodturning is approached. For anyone looking to elevate their turning experience, investing in high-quality replacement carbide cutters is a step towards achieving cleaner, smoother, and more professional results.